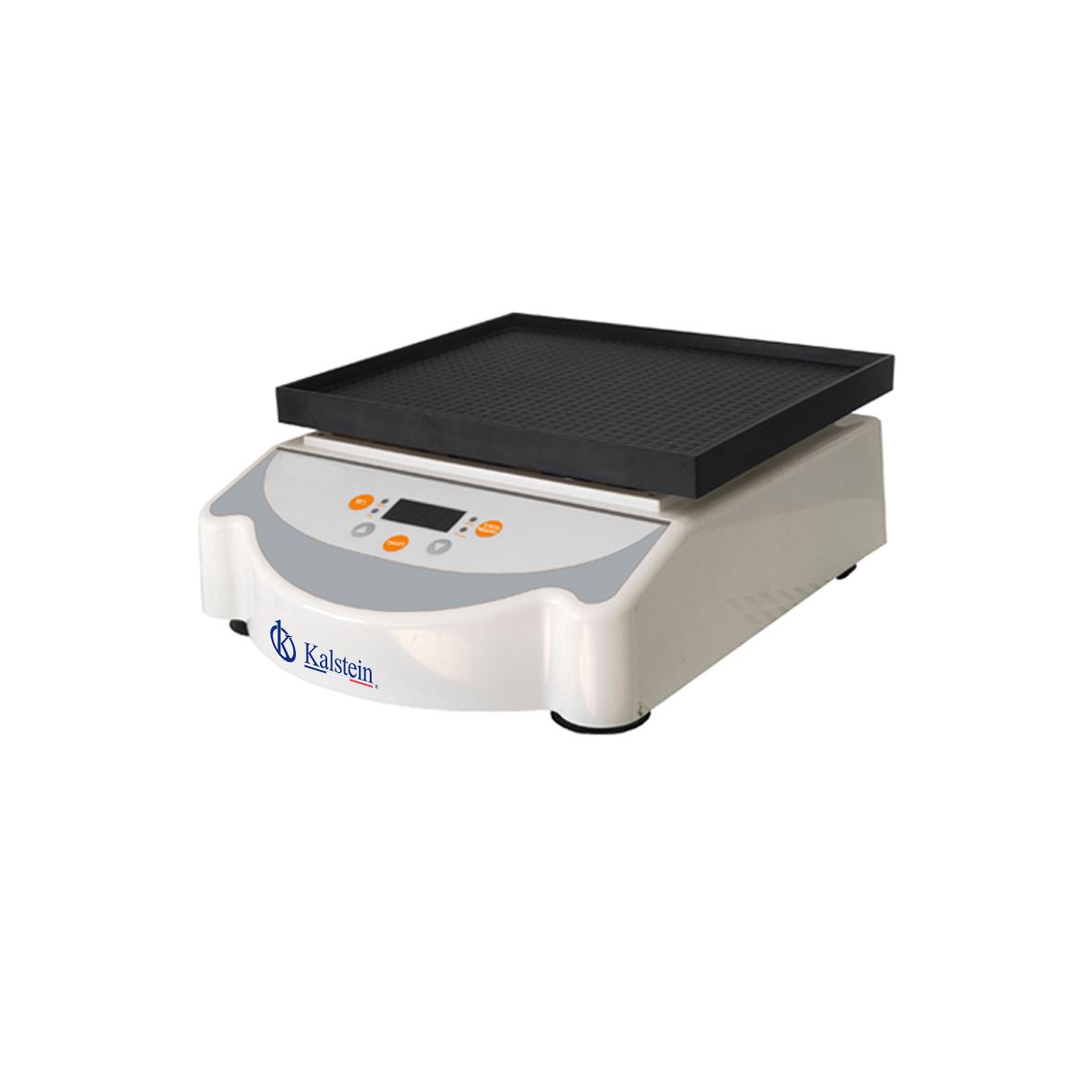

The laboratory shaker are electromechanical devices that are commonly used in specialized chemistry and / or biology laboratories to homogeneously mix solutions and suspensions for tests and trials.

Average stirrers are made up of a plate, which is driven by an electric motor. The sample to be mixed is introduced into a container, which can be a beaker, tube or flask, which is positioned on a vibrating surface.

Fields of application and history of laboratory shakers

These devices can be used in the production of chemicals, cosmetics, food, coatings among others. In research, development, clinical research and education laboratories, the shaker is essential equipment, easily adapting to small spaces and also easy to move from one location to another.

Before the automated shaker, scientists had to perform this process manually, in order to create chemical reactions and other processes. It was not until the beginning of the 20th century that the first automated laboratory shakers began to facilitate this task to the laboratory team, thus being able to achieve a prolonged and controlled shaking.

What is a plate stirrer specifically used for?

The hot plate stirrer has been developed with the purpose of being able to heat and mix fluids contained in laboratory containers such as the Erlenmeyer flask, test tubes and precipitate tubes. It normally has a flat surface on which the containers containing the fluids to be heated or stirred, or heated and stirred, are placed. This surface is manufactured with materials that are characterized by being good thermal conductors such as aluminum or ceramic materials.

Hot plate stirrers have also been developed that are used to exclusively heat sources of infrared radiation (infrared light). The hot plates with stirrer have a heating element (an electrical resistance), a control system (on or off, temperature control, stirring control and its respective motor).

Stirring hotplate combinations range from basic stirring design to explosion proof design for hazardous laboratory applications, while providing you with precise control and repeatability to meet your application needs.

Larger capacity hotplate stirrers are designed for optimal strength to withstand heavy loads. They provide you with the performance you need for your large-scale applications.

- Ceramic, aluminum or stainless steel surfaces

- Hold multiple containers or slides

- Analog or digital control can provide accurate board temperature and monitoring

- Typical operating temperatures are between 100 ° C and 750 ° C

- Stirring speed can be up to 2000rpm

At Kalstein we are MANUFACTURERS and we offer you excellent laboratory shakers at the best PRICES. That is why we invite you to take a look at: HERE