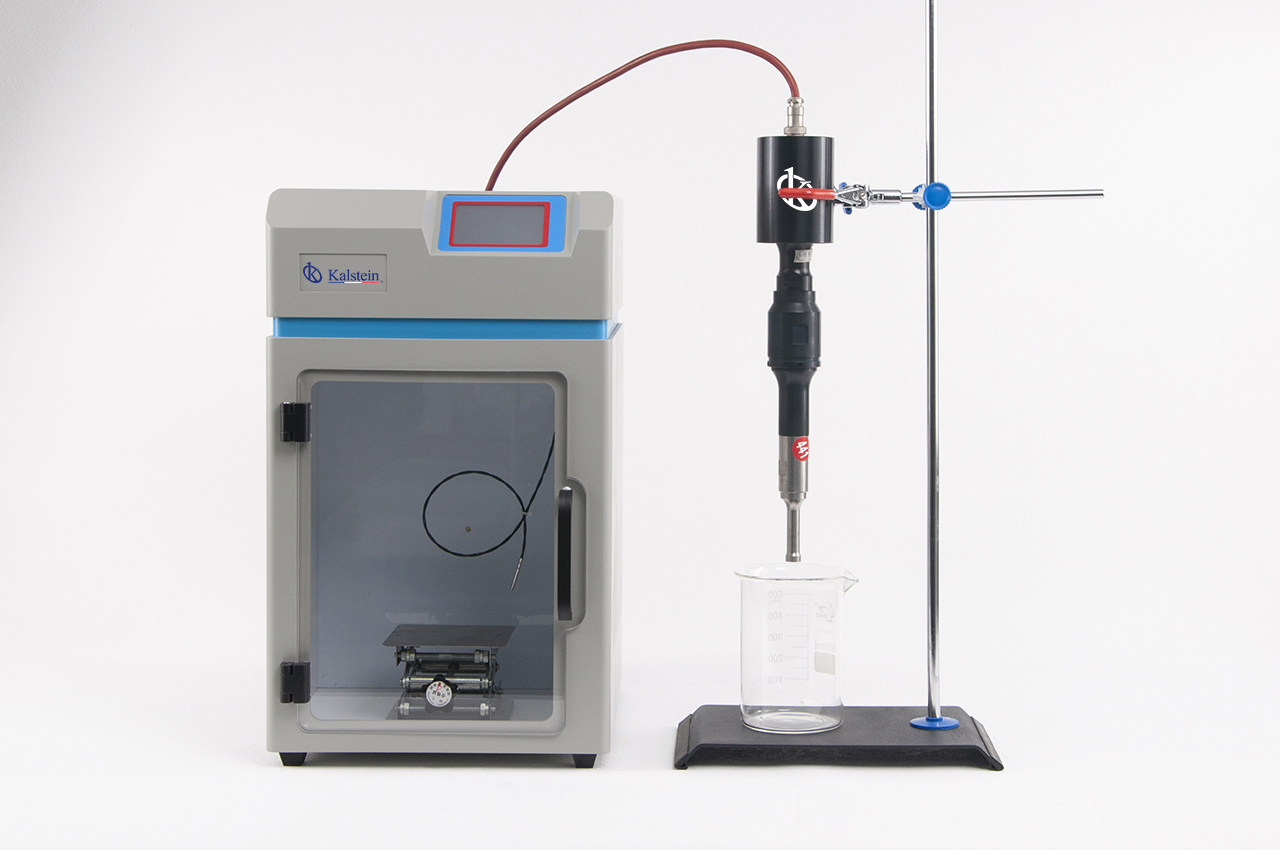

As someone who has had the opportunity to test and evaluate a variety of laboratory equipment, I can confidently say that high-capacity homogenizers are a fundamental piece in any scientific research environment. These devices are designed to break down and mix samples uniformly, ensuring that components are evenly distributed. This capability is crucial for obtaining reproducible and accurate results in various applications, from biotechnology to pharmaceuticals and food research.

Homogenizers work by applying mechanical forces, such as agitation, sonication, or pressure, to disintegrate sample particles. This process not only improves the efficiency of extracting specific compounds but also ensures that the samples are adequately prepared for subsequent analyses.

Features of Homogenizers

Modern homogenizers come equipped with a range of advanced features that make them indispensable in the laboratory. The most notable features include:

-

Processing Capacity: Homogenizers can handle sample volumes ranging from a few milliliters to several liters, making them suitable for both small-scale research and large-scale production.

-

Temperature Control: Some models include cooling systems to prevent sample overheating during the homogenization process, which is essential for maintaining the integrity of heat-sensitive components.

-

Application Versatility: These devices can process a wide range of samples, including tissues, cells, food, and chemicals. Their adaptability is one of the reasons they are so valued in laboratories.

-

Ease of Use: With intuitive touch screens and pre-programmed settings, current homogenizers are easy to operate, even for those with minimal technical experience.

-

Safety and Maintenance: Most models are designed with safety features, such as overheating sensors and automatic stops, and require minimal maintenance, making them very reliable and durable.

Why Do Homogenizers Have This Price?

Homogenizers are a significant investment for any laboratory, and their price reflects the advanced technology and construction quality they offer. There are several reasons why these devices have a high cost:

-

High-Precision Technology: The manufacturing of homogenizers involves the use of high-precision components and durable materials that can withstand the extreme forces applied during the homogenization process.

-

Research and Development: Companies invest considerably in R&D to continuously improve the efficiency, precision, and safety of their homogenizers. This effort translates into devices that offer superior performance and advanced features.

-

Versatility and Adaptability: The ability of these devices to handle different types of samples and volumes also contributes to their price. The more advanced models can be adjusted for various applications, increasing their value and utility in the laboratory.

-

Warranty and After-Sales Service: High-quality homogenizers usually come with extended warranties and technical support, which is crucial for maintaining the equipment in optimal condition over time.

Comparing Homogenizers with Similar Products

In the market, there are several brands of homogenizers, but not all offer the same level of quality and features. Below, I compare Kalstein homogenizers with three prominent brands: Labotienda, VWR, and Scharlab.

|

Features |

Kalstein |

Labotienda |

VWR |

Scharlab |

|

Capacity |

Wide range of volumes |

Limited to certain volumes |

Moderate |

High |

|

Temperature Control |

Advanced |

Basic |

Intermediate |

Advanced |

|

Versatility |

Very high |

Medium |

High |

High |

|

Ease of Use |

Touch screen, pre-programmed settings |

Manual, few settings |

Basic digital interface |

Touch screen, customizable settings |

|

Safety |

Advanced sensors, automatic stops |

Basic |

Intermediate |

Advanced |

|

Maintenance |

Low |

Medium |

Medium |

Low |

|

After-Sales Service |

Excellent |

Limited |

Good |

Good |

As shown, Kalstein homogenizers excel in several key areas, especially in processing capacity, temperature control, and ease of use, making them a preferred choice for many laboratories.

Pros and Cons of Homogenizers

A balanced evaluation of homogenizers involves analyzing both their advantages and disadvantages. Here is a table summarizing the pros and cons:

|

Pros |

Cons |

|

1. High precision and efficiency |

1. High initial cost |

|

2. Versatility for different samples |

2. Requires training for optimal use |

|

3. Advanced temperature control |

3. Can be noisy during operation |

|

4. Easy to operate with intuitive interface |

4. Periodic maintenance necessary |

|

5. Advanced safety features |

5. Size and weight may be an inconvenience |

|

6. Low long-term maintenance |

6. Availability of spare parts may be limited |

|

7. High durability and resistance |

|

|

8. Excellent technical support and warranty |

As you can see, the advantages of homogenizers far outweigh their disadvantages, highlighting their precision, versatility, and ease of use.

Advantages of These Homogenizers

From my experience, homogenizers offer numerous advantages that make them essential in any laboratory. The most notable include:

-

Reproducible Results: The ability to process samples uniformly ensures that the results are consistent and reliable.

-

Time Savings: The efficiency of homogenizers allows multiple processes to be carried out quickly, increasing laboratory productivity.

-

Improved Sample Quality: By effectively breaking down samples, the extraction of desired compounds is improved, which is crucial for accurate analyses.

-

Application Flexibility: These devices are suitable for a wide range of applications, from biotechnology to food and pharmaceutical research.

Other Benefits of Homogenizers

In addition to the advantages mentioned, homogenizers also offer other significant benefits:

-

Reduction of Human Errors: With intuitive interfaces and pre-programmed settings, the possibility of operational errors is minimized, ensuring safer and more efficient processes.

-

Compatibility with Multiple Accessories: Homogenizers can be equipped with a variety of accessories to suit different types of samples and volumes, increasing their versatility.

-

Continuous Innovations: Ongoing improvements in homogenization technology ensure that these devices remain at the forefront, always offering the best possible performance.

Learn About the Opinions on Homogenizers

I have had the opportunity to gather opinions from colleagues and other industry professionals on the use of homogenizers, and the response has been overwhelmingly positive. Many highlight the reliability and precision of these devices, as well as their ease of use and maintenance. Some testimonials include:

-

“Kalstein homogenizers have transformed our laboratory workflow. The precision and reproducibility they offer are unparalleled.”

-

“Despite the initial cost, the investment in a good homogenizer is quickly recovered thanks to the efficiency and quality of the results we obtain.”

-

“The intuitive interface and advanced safety features make these homogenizers very easy to use, even for less experienced staff.”

Frequently Asked Questions

Below, I answer some of the most common questions I have encountered about homogenizers:

What is a homogenizer and what is it used for?

A homogenizer is a device that breaks down and mixes samples to create a uniform distribution of their components. It is used in various scientific applications, such as the preparation of biological, pharmaceutical, and food samples.

What types of samples can be processed with a homogenizer?

Homogenizers are extremely versatile and can process a wide range of samples, including tissues, cells, food, and chemicals. This makes them ideal for research laboratories in different fields.

What is the difference between a homogenizer and a mixer?

While a mixer simply combines sample components, a homogenizer breaks them down and mixes them uniformly, ensuring a homogeneous distribution. This is crucial for obtaining accurate and reproducible results.

Is it difficult to maintain a homogenizer?

No, modern homogenizers are designed to require minimal maintenance. Most models include self-cleaning features and durable components that reduce the need for frequent interventions.

What should I consider when buying a homogenizer?

When buying a homogenizer, it is important to consider the processing capacity, temperature control, application versatility, ease of use, and safety features. It is also useful to check the warranties and technical support offered by the manufacturer.

Why should I choose a Kalstein homogenizer?

Kalstein offers high-quality homogenizers that stand out for their precision, ease of use, and advanced safety features. Additionally, their excellent after-sales service and technical support ensure that your equipment remains in optimal condition over time.

Conclusions on These Homogenizers

In summary, homogenizers are essential tools in the modern laboratory, offering a combination of precision, versatility, and efficiency that is hard to match. Although their initial cost may be high, the investment is quickly justified by the benefits they provide in terms of reproducible results and time savings. Kalstein, in particular, stands out for offering high-quality products with advanced features and excellent technical support. If you are looking to improve the quality and efficiency of your laboratory processes, a homogenizer is undoubtedly one of the best investments you can make.

Are you yearning for top-tier medical equipment, ready to enhance the efficiency of your laboratory? Visit https://kalstein.de/category-product/laboratory-line/homogenizers/ to explore our high-end catalog, packed with the best finds at the most competitive prices. Excellence marks our brand, we innovate and manufacture high-precision equipment, both reliable and durable to meet your needs. Why wait? Make your quick and secure online purchase, take the leap towards the future of medical technology today. https://kalstein.de/