Heating mantles (shakers) are essential tools in many laboratories and medical environments. Their ability to maintain constant and uniform temperatures in various solutions makes them indispensable for a wide range of applications. In this detailed guide, we will explore how to use these devices to achieve the best results, including practical tips and step-by-step tutorials.

Understanding the Operation of Heating Mantles (Shakers)

The Importance of Thermal Homogeneity

Heating mantles (shakers) operate by generating uniform heat around a container, allowing samples to be maintained at a constant temperature. This thermal homogeneity is crucial for many applications, including chemical synthesis and the preparation of biological solutions. Proper use of these devices can prevent temperature variations that could negatively impact experimental results.

Key Components of a Heating Mantle (Shaker)

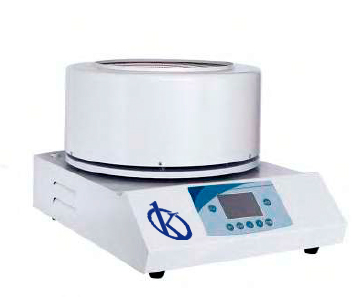

To use a heating mantle effectively, it is important to familiarize yourself with its key components. These include the heating element, temperature control, and in some models, the agitation system. Precise temperature control and the ability to stir solutions are fundamental features that allow for rigorous control of experimental conditions.

Selecting the Right Heating Mantle

Factors to Consider in Selection

Choosing the right heating mantle depends on several factors, including the size of the container, the maximum required temperature, and the need for agitation. It is essential to select a device that can accommodate the volume of your sample and reach the temperatures necessary for your specific application. Compatibility with other laboratory equipment is also an important aspect to consider.

Comparison of Available Market Options

There are numerous models of heating mantles (shakers) available in the market, each with unique features. When comparing options, look for devices with precise temperature controls, integrated safety features, and efficient agitation capabilities. Evaluating user reviews and consulting with laboratory equipment suppliers can provide valuable insights for making an informed decision.

Initial Preparation and Setup

Pre-Use Steps

Before starting to use a heating mantle, it is important to perform a series of preparatory steps. This includes inspecting the device to ensure there is no damage, verifying that all controls are working properly, and cleaning the workspace to avoid contamination. The initial setup also involves adjusting the temperature and agitation controls according to your experiment’s specifications.

Setting Up the Heating Mantle

Setting up a heating mantle involves connecting the device to a secure power source, placing the container in the mantle, and programming the temperature and agitation parameters. Make sure to follow the manufacturer’s instructions to avoid common errors and ensure safe and efficient operation. Regular calibration of the device is essential to maintain precision in results.

Safe and Efficient Use of the Heating Mantle

Safety Practices

The safe use of a heating mantle (shaker) involves following a series of safety practices. Never leave the device unattended while it is operating and always use appropriate personal protective equipment, such as heat-resistant gloves and safety glasses. Additionally, ensure that the workspace is well-ventilated to prevent the buildup of hazardous vapors.

Maintenance and Care

Regular maintenance of the heating mantle is crucial for its longevity and optimal performance. This includes cleaning the device after each use, inspecting cables and connections for signs of wear, and performing periodic calibrations. Proper care not only ensures safety but also enhances the efficiency of the device.

Step-by-Step Experimentation Tutorial

Sample Preparation

Before starting your experiment, prepare your sample by ensuring it is in the appropriate container and that all solutions are properly mixed. Adequate sample preparation is crucial for obtaining accurate and reproducible results. Make sure to follow your laboratory’s specific protocols and use containers compatible with the heating mantle.

Optimizing Results with Heating Mantles

Strategies to Improve Efficiency

To optimize results when using heating mantles (shakers), it is essential to implement strategies that enhance equipment efficiency. One of the most effective strategies is to preheat the mantle before placing the sample. This reduces the time needed to reach the desired temperature and minimizes the risk of thermal variations. Additionally, using lids on containers can help maintain constant temperatures and prevent solution evaporation.

Precise Monitoring and Control

Constant monitoring of temperature and agitation speed is fundamental for obtaining precise results. Use digital thermometers and temperature sensors to verify the readings of the heating mantle. Furthermore, integrating automatic control systems can significantly improve the precision and reproducibility of experiments. These systems allow real-time adjustments and reduce the need for manual intervention.

Specific Applications of Heating Mantles

Chemical Synthesis

In chemical synthesis, heating mantles (shakers) are used to maintain reactions at specific temperatures for extended periods. This is crucial in the production of chemical compounds that require controlled conditions to react properly. Uniform agitation ensures that reactants mix adequately, improving reaction efficiency and the purity of the final product.

Biological Research

In biological research, heating mantles are used to incubate solutions and cell cultures. The ability to maintain a constant temperature is vital for cell viability and experiment reproducibility. Gentle agitation prevents cell sedimentation and ensures a homogeneous distribution of nutrients in the culture medium.

Preventive Maintenance and Long-Term Solutions

Regular Maintenance Plan

Implementing a regular maintenance plan is essential to prolong the lifespan of heating mantles (shakers) and ensure optimal performance. This plan should include cleaning the device after each use, periodically inspecting electrical and mechanical components, and regularly calibrating temperature controls. Preventive maintenance reduces the risk of unexpected failures and ensures the equipment is always ready for use.

Technological Upgrades and Improvements

As technology advances, heating mantles (shakers) also evolve. Keeping up with the latest innovations can provide significant advantages in terms of efficiency and precision. Consider upgrading your equipment to newer models with advanced features, such as digital temperature control, wireless connectivity for remote monitoring, and more durable construction materials.

Case Studies: Successes in Using Heating Mantles

Case Study 1: Drug Synthesis

A drug synthesis laboratory significantly improved the efficiency of its processes by using state-of-the-art heating mantles. They implemented an automated monitoring system that adjusted temperature and agitation in real-time, reducing human errors and increasing experiment reproducibility. As a result, the purity of synthesized compounds improved by 20%, and reaction times were reduced by 30%.

Case Study 2: Stem Cell Research

In a stem cell research center, the use of heating mantles (shakers) enabled optimal conditions for culturing pluripotent stem cells. Gentle and constant agitation prevented cell aggregate formation, improving cell viability and experiment efficiency. Additionally, the ability to maintain precise temperatures was crucial for the controlled differentiation of cells into various cell types.

Recent Innovations in Heating Mantles (Shakers)

Integration of Artificial Intelligence

One of the most recent innovations in the field of heating mantles is the integration of artificial intelligence (AI). AI systems can analyze real-time data and automatically adjust temperature and agitation parameters to optimize experimental conditions. This not only improves precision but also reduces the laboratory staff’s workload, allowing them to focus on more complex tasks.

Advanced Materials

The development of new materials for heating mantles has led to significant performance improvements. Materials such as graphene and advanced metal alloys offer superior thermal conductivity, allowing for faster and more uniform heating. Additionally, these materials are more resistant to corrosion and wear, increasing the equipment’s durability.

Conclusion: Maximizing the Potential of Heating Mantles (Shakers)

Summary of Benefits

Heating mantles (shakers) are versatile and essential tools in numerous fields of research and industry. Their ability to maintain constant temperatures and provide uniform agitation is crucial for the success of many experiments and production processes. By following the best practices described in this guide, users can maximize the potential of these devices, obtaining accurate and reproducible results safely and efficiently.

Future of Heating Mantles Use

Looking to the future, continuous innovation in the design and functionality of heating mantles (shakers) promises even more performance and application improvements. The adoption of advanced technologies, such as artificial intelligence and new materials, will continue to drive the development of more efficient and effective laboratory equipment, facilitating significant advances in scientific and medical research.

With this complete guide, we hope to have provided a clear and practical understanding of using heating mantles (shakers). By following these tips and step-by-step procedures, users can ensure they are using their equipment optimally, contributing to success and innovation in their respective fields.

If you want to explore the high-end product catalog we have for you at KALSTEIN, visit us at https://kalstein.de/category-product/laboratory-line/heating-mantle-stirrer/ We assure you that through our easy and feasible online purchase channels, you will find the best prices on the MARKET. Remember that at KALSTEIN, we MANUFACTURE high-level laboratory equipment for SALE. https://kalstein.de/